DTF Hot Peel Film revolutionizes print-on-demand apparel manufacturing by offering precise, high-quality printing on diverse materials, including fabrics and plastics. Its versatility, speed, cost-effectiveness, and vibrant color durability make it popular for hoodies, t-shirts, and light fabrics. By using a direct-to-film printer and following proper preparation and peeling techniques, businesses can create unique, personalized products with excellent adhesion and longevity.

Discover the revolutionary power of DTF Hot Peel Film for precise, crisp transfers. This innovative technology is transforming the way professionals approach printing, offering unparalleled cleanliness and efficiency. From its seamless application to effortless peeling, DTF Hot Peel Film ensures every detail is captured perfectly. Explore the benefits that make it a top choice, from enhanced accuracy to time-saving advantages. Uncover best practices for optimal results and learn why this film is a game-changer in the printing industry.

- Understanding DTF Hot Peel Film Technology

- Benefits of Using DTF for Clean Transfers

- Application and Best Practices for Optimal Results

Understanding DTF Hot Peel Film Technology

DTF Hot Peel Film technology has revolutionized the world of print-on-demand and custom apparel manufacturing. This innovative process allows for precise, high-quality printing on a wide range of materials, including fabrics, plastics, and more. The key lies in its ability to deliver crisp, clean transfers, ensuring every detail is accurately reproduced.

When it comes to applications, DTF printing for hoodies, custom t-shirts, and even light fabrics has gained immense popularity. The versatility of this technology enables businesses to offer unique, personalized products with intricate designs. By using the DTF Hot Peel Film, printers can achieve excellent adhesion and durability, making it an ideal choice for creating long-lasting, visually appealing garments and items.

Benefits of Using DTF for Clean Transfers

Using DTF (Direct to Fabric) Hot Peel Film offers numerous advantages when it comes to achieving crisp and clean transfers on a variety of fabrics, making it a preferred method for many clothing brands and custom graphic tee creators. One of its key benefits is speed; DTF allows for quick printing without the need for complex setups or specialized equipment, enabling businesses to turn designs into tangible products in no time. This efficiency not only saves time but also reduces costs, making it an attractive option for those looking to streamline their production process.

Additionally, the DTF Hot Peel Film ensures long-lasting durability and vibrant colors, even on moisture-prone fabrics like cotton. The direct application of the design onto the fabric minimizes bleeding or smudging, resulting in high-quality dtf prints that maintain their integrity over time. This feature is particularly valuable for clothing brands aiming to create visually appealing and long-lasting products, whether it’s for a fashion line or custom graphic tees.

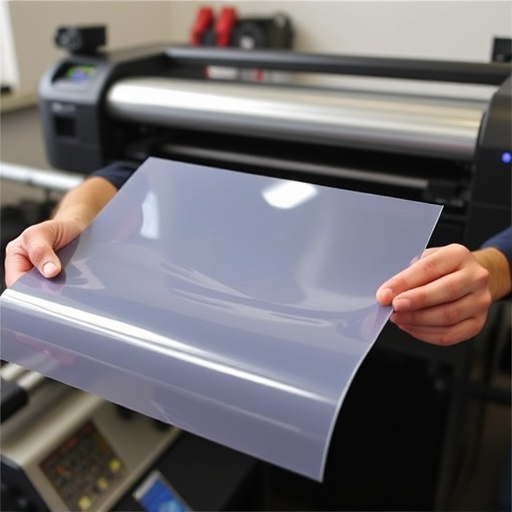

Application and Best Practices for Optimal Results

When applying DTF Hot Peel Film for optimal results, start by ensuring your surface is clean and free of any contaminants. This includes dust, oils, or previous printing residue. A thorough cleaning with appropriate solvents or specialized cleaners can help achieve a smooth base for your transfer.

For best practices, use a direct to film (DTF) printer to produce precise images. Position the film correctly on the print bed and calibrate your settings according to the manufacturer’s guidelines. After printing, allow the film to reach room temperature before attempting the peel. A gentle pull at the edge can initiate the peeling process, but be cautious not to stretch or tear the film. The hot peel should occur smoothly, revealing a crisp, clean transfer ready for application onto your desired substrate.

The DTF Hot Peel Film technology offers a game-changing approach to achieving crisp, clean transfers in various applications. By understanding its unique benefits and best practices, users can unlock optimal results, ensuring precision and efficiency in their projects. This innovative film is a testament to the evolving world of transfer technology, providing a simple yet powerful solution for those seeking exceptional quality and convenience.