The DTF Hot Peel Film is a game-changer in print and finish applications, offering unparalleled precision and versatility for DTG (Direct-to-Garment) printing. Its unique "hot peel" technology ensures detailed and vibrant prints on various substrates from fabrics to plastics, streamlining the process, reducing preparation time, and delivering consistent high-quality results. Integrating this film into production processes enhances efficiency and finish quality, with custom DTF gang sheets providing versatility for diverse projects. The ease of use expedites turnaround times, making it ideal for fast-paced industries. The film's durability ensures long-lasting, visually appealing products, suitable for apparel, signage, and automotive sectors, revolutionizing custom apparel production.

Discover how DTF Hot Peel Film is transforming the landscape of final finishes. This innovative material offers unique properties and benefits that enhance visual appeal, durability, and practicality in various production processes. By integrating DTF Hot Peel Film into your workflow, you can achieve remarkable results, from improved aesthetics to enhanced product longevity. Explore the impact and unlock the potential of this game-changing technology.

- Understanding DTF Hot Peel Film: Properties and Benefits

- Integrating DTF Hot Peel Film into Production Processes

- The Impact on Final Finishes: Visuals, Durability, and Practicality

Understanding DTF Hot Peel Film: Properties and Benefits

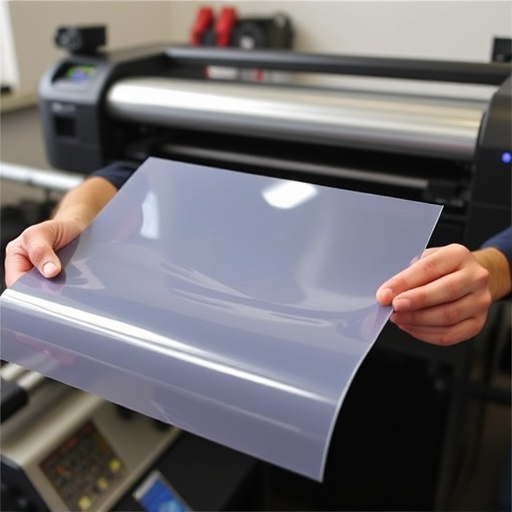

DTF Hot Peel Film is a revolutionary material that has transformed the world of print and finish. This specialized film offers unique properties, making it an excellent choice for various applications. Its primary function lies in facilitating the transfer process, especially in DTG (Direct-to-Garment) printing and other similar techniques. The term “hot peel” refers to its ability to easily separate from the substrate after heating, ensuring a smooth and precise transfer of designs.

This film’s benefits are numerous. It provides a high level of precision during the dtf transfer by size, allowing for detailed and vibrant prints. DTF Hot Peel Film is also known for its versatility; it can be used on a wide range of materials, from fabrics to plastics, making it a go-to solution for dtf transfer printing. The printing process becomes more efficient and user-friendly with this film, as it reduces preparation time and ensures consistent, high-quality results.

Integrating DTF Hot Peel Film into Production Processes

Integrating DTF Hot Peel Film into production processes involves a strategic shift towards enhanced efficiency and finish quality. This innovative material streamlines operations by simplifying the peeling process, eliminating the need for harsh chemicals or labor-intensive techniques. Manufacturers can achieve precise, clean cuts, resulting in improved accuracy during application, especially in complex designs.

The seamless integration of DTF Hot Peel Film into workflows promotes better productivity. Custom DTF gang sheets offer versatility, catering to diverse project needs. Their superior dtf durability ensures long-lasting results, making them ideal for high-volume production runs or demanding applications like apparel and signage. Moreover, the ease of use with DTF heat transfers expedites turnaround times, meeting the demands of fast-paced industries.

The Impact on Final Finishes: Visuals, Durability, and Practicality

The use of DTF Hot Peel Film has a significant impact on the final finishes of various products, particularly in the realm of dtf heat transfers and dtf custom apparel. Visually, this innovative film enhances the overall aesthetics by enabling precise, vibrant, and detailed designs that are both durable and long-lasting. The ability to produce intricate patterns without compromising quality ensures that the finished products stand out, making them ideal for brands looking to create a unique and memorable visual impact.

Moreover, DTF Hot Peel Film boosts durability, ensuring that the final finishes withstand everyday use and exposure to various elements. This feature is especially beneficial in industries where longevity is crucial, such as apparel, signage, and even automotive applications. Additionally, its practicality cannot be overlooked, particularly with fast delivery services becoming the norm. DTF heat transfers processed with this film can be quickly and efficiently produced, meeting the demands of businesses that require prompt turnaround times without sacrificing quality, making it a true game-changer in the market for custom apparel and similar products.

The DTF Hot Peel Film has proven to be a game-changer in various industries, offering significant advantages in production processes and final finishes. Its unique properties, including ease of integration and superior durability, make it an essential consideration for professionals seeking high-quality, efficient outcomes. By embracing this innovative technology, manufacturers can enhance visual appeal, ensure longevity, and streamline their workflow, ultimately elevating the overall quality of their products.