DTF Hot Peel Film is a game-changing technology for garment printing, offering faster production, enhanced print quality, and reduced waste compared to traditional methods. Its versatility extends across industries like packaging and automotive interiors, boosting productivity and brand experiences. By assessing current setups, sourcing compatible film, and optimizing heat press settings, businesses of all sizes can leverage DTF's efficiency for improved performance and accessible innovation.

Discover the transformative power of DTF Hot Peel Film and its real-world impact. This innovative material is revolutionizing industries, offering unparalleled benefits in printing and packaging. From enhanced durability to swift peeling, it provides an efficient solution for businesses seeking a competitive edge.

Uncover the secrets behind its success through real-life applications and learn how brands are achieving remarkable results. Additionally, this guide offers practical steps to help you transition smoothly to DTF Hot Peel Film, unlocking new possibilities for your projects.

- Unveiling the Benefits of DTF Hot Peel Film

- Real-World Applications and Success Stories

- How to Make the Switch: A Practical Guide

Unveiling the Benefits of DTF Hot Peel Film

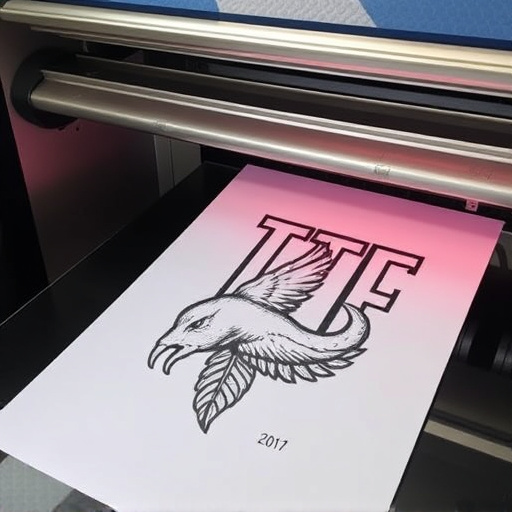

The switch to DTF Hot Peel Film is transforming the way professionals approach garment printing. This innovative technology offers a range of benefits that cater to both small-scale and bulk order needs. Unlike traditional methods, DTF (Direct to Film) hot peel film streamlines the printing process by eliminating the need for multiple coats of vinyl, resulting in crisper, more vibrant prints with exceptional durability.

For businesses engaging in dtf garment printing, this advancement means faster production times and reduced material waste. Efficient file preparation plays a crucial role here; with the right software and techniques, designers can create intricate DTF files, ensuring smooth transfer to the film and ultimately, the garments. Moreover, the ability to handle dtf bulk orders efficiently makes DTF Hot Peel Film a game-changer for businesses looking to meet high-demand orders while maintaining print quality.

Real-World Applications and Success Stories

The versatility of DTF Hot Peel Film is evident in its real-world applications, where it has transformed various industries and use cases. From packaging and signage to POP displays and even automotive interiors, this innovative film is making waves. Businesses across sectors are reporting significant enhancements in their production processes thanks to its ease of use and efficient peeling mechanism.

Success stories abound, with many companies highlighting the improved productivity and reduced waste associated with DTF Hot Peel Film. For instance, a small local business that switched to DTF for their packaging needs noted a 20% increase in throughput without compromising quality. Another case study involved a large-scale retailer who implemented DTF color matching for in-store displays, resulting in a more visually appealing and consistent brand experience across all stores. Furthermore, the superior durability of DTF has been a recurring theme in user reviews, ensuring that designs last longer and maintain their impact even under demanding conditions.

How to Make the Switch: A Practical Guide

Switching to DTF Hot Peel Film is a straightforward process that can dramatically enhance your printing capabilities. Start by evaluating your current setup and identifying areas where DTF can bring improvements, such as faster production times, enhanced image quality, and reduced material waste. Next, source high-quality DTF Hot Peel Film, ensuring it’s compatible with your printer model and intended applications.

When making the switch, consider adjusting your dtf heat press settings to optimize print results. The key lies in finding the right balance between temperature and pressure for your specific film type. Experiment with different settings for best outcomes, focusing on achieving vibrant designs without compromising precision. Even small orders can benefit from DTF’s efficiency, allowing businesses of all sizes to embrace this innovative printing method.

Switching to DTF Hot Peel Film offers a compelling blend of enhanced efficiency, reduced waste, and improved product quality. As evidenced by real-world applications and success stories, this innovative film not only meets but exceeds the expectations set by traditional methods. By following the practical guide provided, businesses can navigate the transition seamlessly, reaping the benefits in terms of both cost savings and environmental impact. Embrace the future of packaging with DTF Hot Peel Film and unlock substantial results.